The Basic Principles Of Digital Printing

Table of ContentsThings about Digital PrintingGetting My Digital Printing To WorkNot known Details About Digital Printing Not known Facts About Digital PrintingThe Only Guide to Digital Printing10 Easy Facts About Digital Printing ShownSome Known Questions About Digital Printing.The Digital Printing Statements

Customization also permits organizations to attract attention in a jampacked market by producing distinct marketing products that distinguish them from their competitors. Among the primary advantages of electronic printing is the capability to print variable information. Each printed piece can be one-of-a-kind, enabling companies to develop individualized advertising products that speak straight to their target market.Digital printing likewise allows for personalization in the layout of advertising products (Digital Printing). With digital printing, businesses can create styles that are unique and tailored to their certain needs.

10 Easy Facts About Digital Printing Shown

By publishing smaller sized amounts of advertising materials, companies can reduce waste and avoid the need for excess inventory. Digital printing is additionally functional.

By making use of various products and styles, companies can create unique marketing products that attract attention from their rivals and stand out from their target audience. Digital printing additionally supplies uniformity. With conventional printing methods, there is frequently variation in between prints because of differences in ink coverage, stress, and other factors.

This uniformity can assist develop customer trust fund and reputation, revealing that business is dedicated to offering top notch products. Consistency is particularly vital for services that intend to construct customer trust fund and integrity. By guaranteeing that every print corresponds, services can show that they are committed to offering high-grade materials and taking notice of the details.

All about Digital Printing

Furthermore, electronic printing creates much less waste since it can print as needed and in smaller amounts, decreasing the demand for excess stock and materials. Digital printing also uses much less power compared to traditional printing techniques. Digital printers do not call for as much power to operate, as they do not require to warm up as a lot or make use of as much power to run.

The 5-Second Trick For Digital Printing

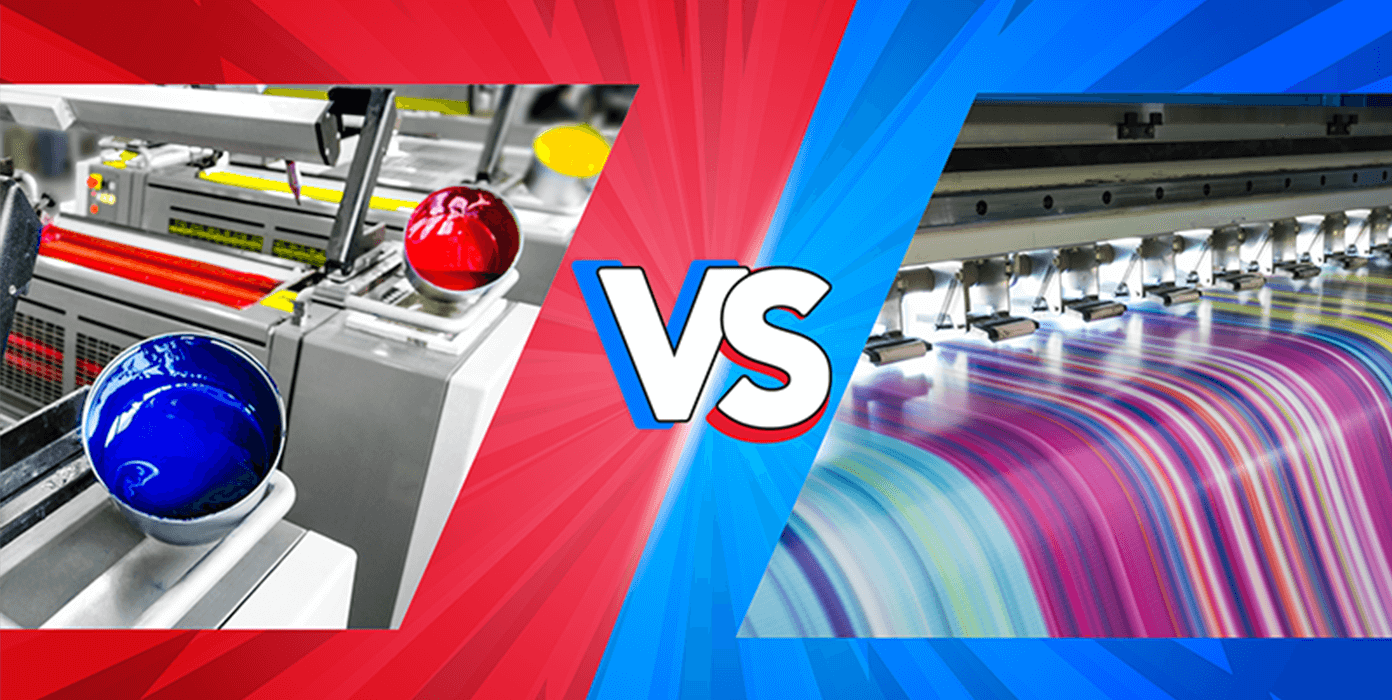

Balanced out printing calls for a plate for every color printed. Standard offset printing is a print method that uses aluminum plates to transfer ink onto a rubber sheet (frequently described as a "covering"). The image is then rolled onto the printing surface area. This printing method is considered "countered" since the ink is not transferred to the paper directly.

Not known Facts About Digital Printing

Although the devices's set-up prices are high at first, extra devices become reasonably much less pricey as the quantity rises. Countered printing permits a large range of print materials to be made use of during production. It allows the printer to use various paper kinds, personalized finishes, and numerous inks. The top notch pictures created through countered printing make it the recommended method, particularly amongst graphic designers, when seeking the best shade recreation, detail, and professional-looking prints.

For electronic inkjet printing, ink is moved directly onto the surface area. Rather than depending on light weight aluminum plates and rubber coverings to move a photo, electronic printing uses liquid ink throughout production.

The Only Guide for Digital Printing

Better color fidelity describes both the precision of the shades and their equilibrium in the style. Because offset printing can mix custom-made shade inks for each and every work, it will normally obtain the shades spot-on. Functions similarly well on nearly any kind of sort of product. Reliable, superior photo high quality. Trust countered printing for tidy, unique kinds and photos without touches or areas.

It sets you back a great deal to start an offset work. You need to invest cash right into producing the plates, which requires time. When you have actually spent it, this page all of the materials are ready to go, and you'll invest less on large balanced out jobs than an electronic print, which is about the exact same per piece no issue how huge the job gets.

Each print equals. You run the risk of less odd variations brought on by imbalances in water and ink. Digital printing is less pricey for low-volume jobs. The price each goes down for digital printing, so at some time, they crisscross. Transforming details within a single print task. As an example, claim you were printing out postcards promoting a concert.

The 10-Minute Rule for Digital Printing

While digital printing or inkjet printing is the favored choice in the existing times, there are engaging factors to convert from offset to electronic printing systems. When printing countered or digitally, vital choices and processes are included in shade matching.

Whichever the instance, the shade will certainly require to be matched. Shade matching of digital printer ink is no much longer challenging with dyes read review and pigments. Industrial inkjet printing supplies versatility for printing on several substrates. Digital printing is suitable for clients who do not call for longer runs and warehousing materials.

One benefit of digital printing is selecting from a broad variety of digital substrates. With digital printing, the cost of the substratum in the total work is tiny.

The 30-Second Trick For Digital Printing

drop-on-demand is the second printing technology to take into consideration. Continual inkjet systems need significant upkeep, more driver training, and higher downtime. Equipment prices in inkjet printing are far reduced than balanced out printing as there are no plate-making, plates, and press expenditures. Beyond the you could try these out capital expenditure, the prepress equipment and printing machine need very proficient operators in balanced out printing, which adds labor expenses.